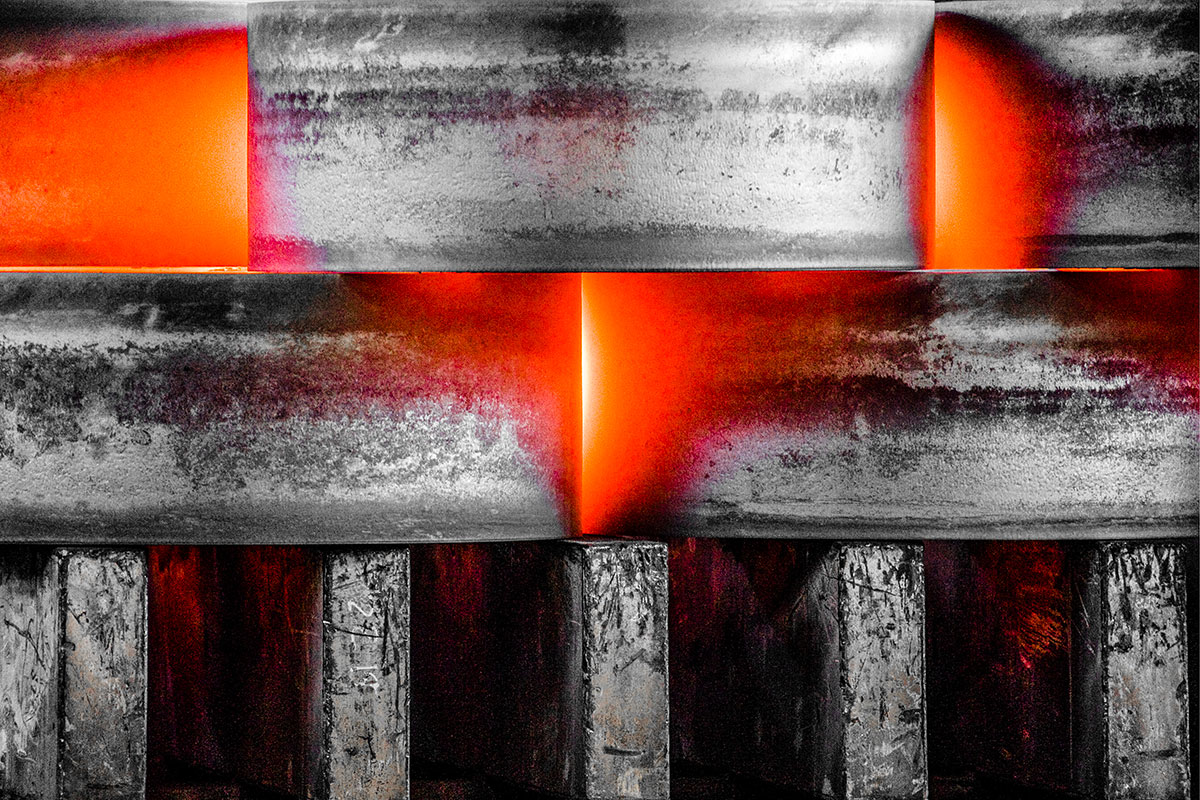

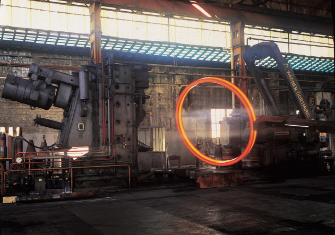

Where tradition and innovation work together.

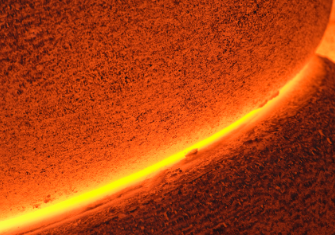

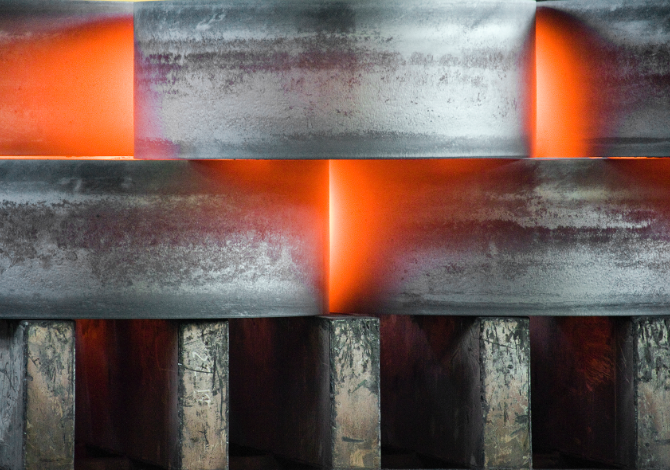

IRE-OMBA’s Bergamo and Seriate plants produce rectangular/shaped section hot-rolled rings in all types of steel plus light alloys, super alloys and non-ferrous materials.

The rings can be supplied in natural raw, rough treated and sanded, roughened, or finished to design. The production capacity of the plants exceeds 40,000 weeks, with an average export of 80%. The production range covers rings with weight ranging from 15 to 6,500 kilograms.

MATERIAL CATEGORY

- Carbon and Low alloy steels

- Alloy steels

- Bearing steels

- Tool steels

- Austenitic Stainless steels

- Duplex & Super-Duplex Stainless steels

- Martensitic Stainless steels

- Precipitation Hardening steels

- Nickel Based superalloys